Finding Right Partner for Digital Medical Surgery Applications

Digital Medical Surgery Tools Are Becoming Commonplace

Embedded systems have infiltrated the medical/healthcare space in a huge way. Nearly every aspect of the hospital is run by an embedded system in some way. That starts at the admitting office and runs the gamut through patient discharge, and everything in between. The embedded system, often a panel PC, is used for surgery, testing, and monitoring the patient’s vital signs 24/7.

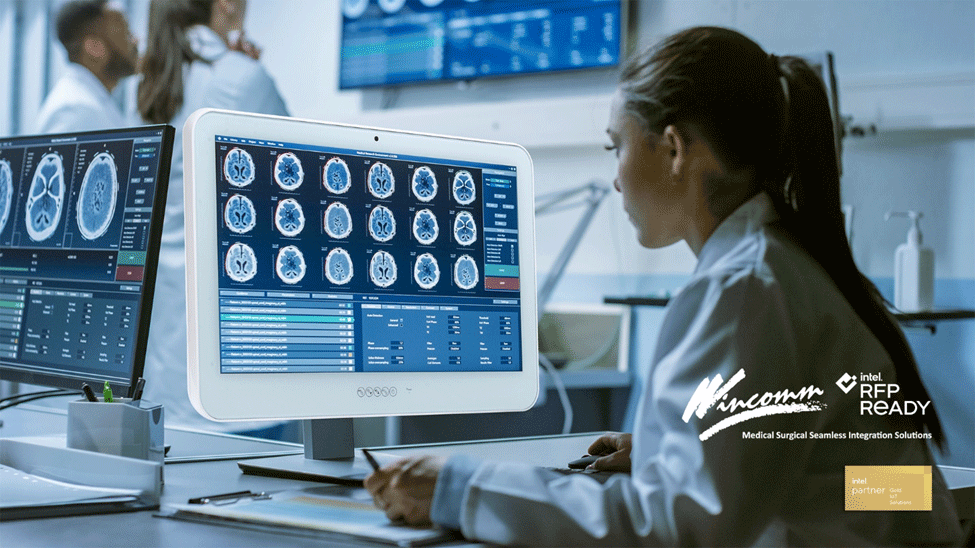

As the performance of the embedded system and the associated technologies has improved, more uses are being found. One such application is in the operating room. For example, doctors can use imaging tools to diagnose health problems without having to perform exploratory surgery, and they can use those same imaging tools to track treatment progress. The use of embedded systems in healthcare also makes tracking vital signs virtually instantaneous.

Fig. 1 For medical image diagnosis, such as CT, an useful all in one PC is a good hand to review and track these data effectively.

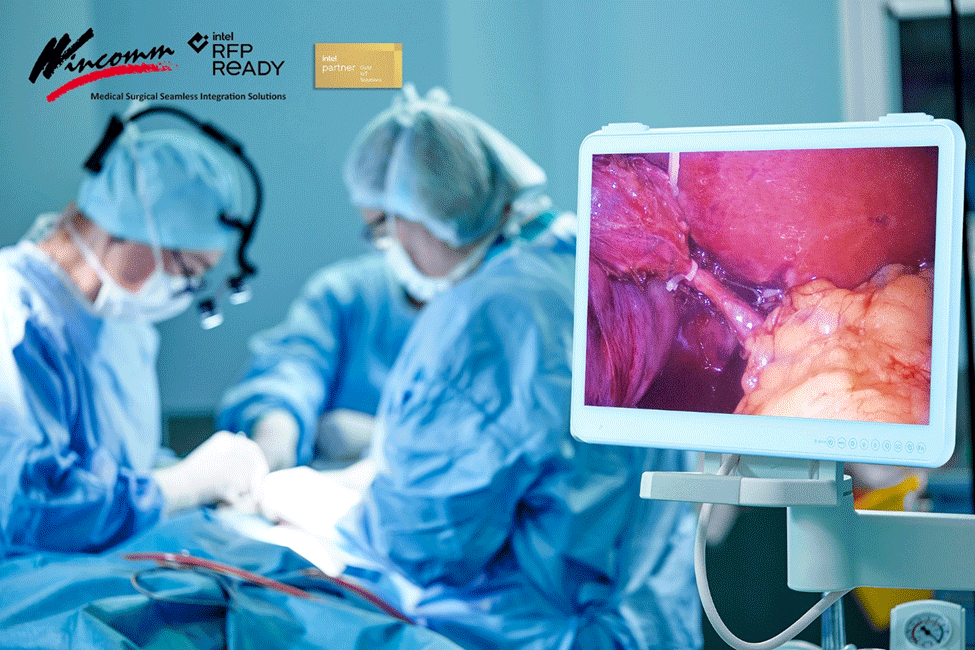

Combining those embedded systems with robotics technologies results in a tool that’s invaluable for a surgeon, as it provides more precision that a human could ever offer. Robotics are revolutionizing the field of medicine. From critical procedures to routine tasks, physicians and hospitals are adopting the use of this advanced technology to reduce costs, enhance precision, and increase safety.

The Digital Healthcare Boom

It’s no secret that digital healthcare is a thriving industry. That upswing mainly results from two points. First, the technology is rapidly advancing and becoming more mainstream/commonplace. Second, the pandemic forced people to remain at home, so telehealth became a necessity. And we know that necessity is the mother of invention. The patient’s mindset is somewhat different as well, meaning that there’s less hesitancy to offer up personal information, either verbally or through a digital portal.

At the same time, while Cloud computing is commonplace and readily accepted, that’s not the case for medical applications due to potential security issues. Conversely, Edge computing is a popular alternative, as the information likely doesn’t leave the premises. This is especially true for medical procedures that occur within the confines of the medical research center.

Another important factor in digital health equipment is that the flow of information can spread far beyond the operating room. This means that as soon as the patient comes out of surgery, all the relevant information is sent to various affiliates. This could include the floor staff, where the patient will be transferred to, the patient’s general practitioner, so follow-up treatment is available and appropriate, and even the billing department so errors are minimized.

The key point is that medical solutions must:

• be easy to use

• last for multiple generations (three to five years is typical)

• be cost effective

• result in the best solution for both the surgeon and the patient

One good example is the imaging tools that are now employed by physicians. The speed and precision of video and imaging, including compression when needed, have improved vastly in just the last few years. There is less latency than before, which is obviously a key to making real-time decisions. For example, a doctor could be looking at an image from an endoscope, and that image could be enhanced using AI techniques and potentially viewed by another doctor at a different location. It could also be infusion information that is specific to the patient, like from past procedures or family history.

Seamless Technology Integration

Seamlessly integrating the various pieces of data along with the various types of medical equipment is a non-trivial task. You may have video in different formats, simultaneously coming through different interfaces, such as USB and/or HDMI. There may also be input from a barcode reader, a smart card reader, or RFID. And keep in mind that the user/operator is likely someone who is well trained in surgical procedures and not interested in computer training.

While many of the technologies being deployed for medical applications has been around for a while, it wasn’t until fairly recently that the platforms themselves are stable enough to be trusted for surgical and other critical healthcare applications.

Another far less obvious reason for the recent advancements has to do with the power—or reduction in power—that’s needed to drive these platforms. They can either be connected to a conventional wall outlet using an uninterruptable power supply (UPS) as a backup energy source. Or in some cases, the systems can operate completely untethered for field administration by emergency personnel.

When it comes to redundancies, the UPS is a key component. Should the power go down at an inopportune time, like during a surgical procedure, you need to have the confidence that the procedure will not be interrupted. A backup time of about two hours is the generally accepted specification. Other safety methods could be employed as well, depending on how critical the system is. In addition, it’s vital to ensure that the data is always backed up to a safe and secure place, according to HIPAA regulations.

Fig. 2 Wincomm innovated new medical PC designed for Operating Room, WMP-24M series.

User Training - Finding the Right Solutions Partner Is Key

Obviously, the number people permitted in an operating room must be limited. However, someone amongst the group must be trained in how to correctly operate the computer equipment. Simple computer maintenance would be permitted, but you wouldn’t want someone opening the computer case during a medical procedure. Hence, training is vital. And that training must include what “fixes” are permissible during a surgical procedure and what would have to wait for more highly trained administrators.

Some embedded systems providers are more adept at applications like these that require such high levels of precision. For example, Wincomm Technologies is better suited than its competitors to offer this technology for a host of reasons. First, it is a longstanding company with deep experience and many years in the medical/healthcare space. That includes working directly with medical professionals to hone their craft. That direct input from the doctors who are actually using the tools is invaluable.

To that end, when modifications or customization is needed, Wincomm’s experienced design team is likely up to the task. And such modifications are norm when working with medical professionals.

Second, Wincomm has worked closely with the software vendors to ensure that there is a very tight hardware-software integration. And as new designs and upgrades roll out, that connection with the software and firmware, including the potentially complex APIs, greatly simplifies the product evolution process. And when modifications are needed, they can be implemented directly by the experts at Wincomm. Due to the potential expense of such equipment, hospitals want the systems to have as long a shelf life as possible. Hence, upgrades are usually welcome, as they can stave off having to purchase brand new equipment. Those upgrades can also serve to maintain compliance should regulations change.

Third, Wincomm offers a very high level of support. If an operating system recovery is needed, you want that issue placed into the hands of an experienced team. And if users require training or help with integration, Wincomm has the answers. This last point is crucial when dealing with non-technical users in a potentially life-threatening (or saving) application. The user interface on a surgical tool is often a touch interface, so proper training is always required. Wincomm places a two-year guarantee on its platforms, with longer guarantees to five or ten years readily available. Even after that time, Wincomm will support its platforms, generally for 15 years or longer.

Finally, it’s important to work with a supplier that has experience working in potentially hazardous environments. The operating room is typically exposed to various liquids that could play havoc with an embedded computer that’s not properly protected. Hence, antibacterial housings are required. In the case of Wincomm’s panel PCs, they are waterproof up to and beyond the IP54 specification for hygienic control. In addition, the doctor may need an alternate type of input, as his or her hands may not be allowed to make contact with the computer. Those alternatives include foot pedals and/or voice input.

The bottom line is the lives are at stake in the operating room, and there is very little room for anything but perfection. Work with a team like Wincomm that’s been there and has excelled and continues to evolve with leading-edge technology.

About Wincomm

Wincomm is one of Taiwan’s leading manufacturer of industrial computer and embedded computer products. Wincomm designs and develops all in one panel PC, large size all in one digital signage system, rugged box PC and embedded software products for a broad range of industries and applications. Wincomm aims to provide hardware and software integrated solutions for the most variant environments such as industrial automation/ human machine interface control, digital signage / infotainment Kiosk, and medical computing.

|