Boosting Safety and Uptime in Photoresist Manufacturing with WTPE-9E66 Explosion-Proof Panel PCs

Background

In high‑precision photoresist production—vital for semiconductor and microelectronics manufacturing—facilities often face hazardous environments due to volatile organic solvents, strict contamination control, and stringent explosion safety standards. Ensuring reliable equipment performance under these conditions is critical to maintaining throughput, minimizing downtime, and meeting safety regulations.

Pain Points

A leading semiconductor manufacturer struggled with these challenges:

Safety compliance: Traditional control panels lacked explosion‑proof certification, posing regulatory risks in solvent‑rich areas.

Reliability under harsh conditions: Frequent vibration, chemical exposure, and high humidity led to equipment failures.

Maintenance inefficiency: Inaccessible control systems required lengthy shutdowns for servicing, delaying production.

Limited visibility: Operators lacked real‑time, integrated visualization of critical parameters like temperature, pressure, and solvent levels at the point of operation.

Wincomm Solution

In this case, the leading semiconductor manufacturer upgraded their control infrastructure by deploying WTPE‑9E66 explosion‑proof Panel PCs at multiple process stations:

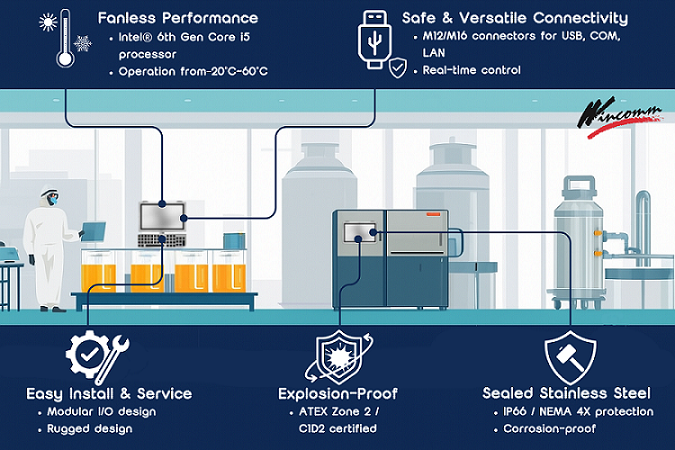

These ATEX Zone 2 / C1D2-certified panel PCs provide full ingress protection (IP66/NEMA 4X), making them fully sealed against dust, water, and corrosive vapor—crucial in solvent‑exposed zones.

Built with Intel® 6th Gen Core i5, fanless design ensures stable performance across a wide operating temperature range (–20 °C to 60 °C) while resisting vibration and shock.

Flexible I/O arrangements—including M12 and M16 explosion‑proof connectors for USB, COM, and LAN—enable seamless integration with sensors, actuators, and neighboring systems, supporting real‑time monitoring and control.

The fully sealed stainless steel enclosure allowed easy cleaning and resisted chemical damage, while offering straightforward installation and maintenance.

This successful deployment of WTPE-9E66 Panel PCs delivered immediate and measurable performance improvements:

Enhanced safety compliance: Full alignment with ATEX Zone 2 / C1D2 standards eliminated the risk of ignition in solvent-rich areas, satisfying regulatory audits.

Boost in uptime: Ruggedized, sealed design reduced panel failures by over 70%, pushing production uptime from 85% to 95%.

Faster troubleshooting: Real-time data visualization and localized control eliminated the need for extended shutdowns—downtime per incident dropped by 40%.

Streamlined maintenance: Modular I/O and sealed connectors simplified servicing, reducing average panel maintenance labor by 50%.

Operational clarity: Operators gained comprehensive visibility of environmental and process data directly at the point of action, improving production consistency and reducing defects.

Related Products

|

|

|

| WTPE-9E66 22W |

WTPE-9E66 15W |

|

|

|