Clean Room Flow Automation Control

Background

Maintaining high standards of hygiene has always been important in any facilities, such as food and pharmaceutical processing plants, that are involved in the manufacturing and/or processing of anything—food, drinks, or drugs—that will ultimately be ingested by human beings or injected or inserted into them.

Further exacerbating the problem is the current COVID-19 pandemic, which requires all personal -- managers, technicians, workers, maintenance, and janitorial staff -- to wear masks, practice social distancing, and maintain personal hygiene including the regular washing of hands.

Pain Points - Why Smart Hygiene Control

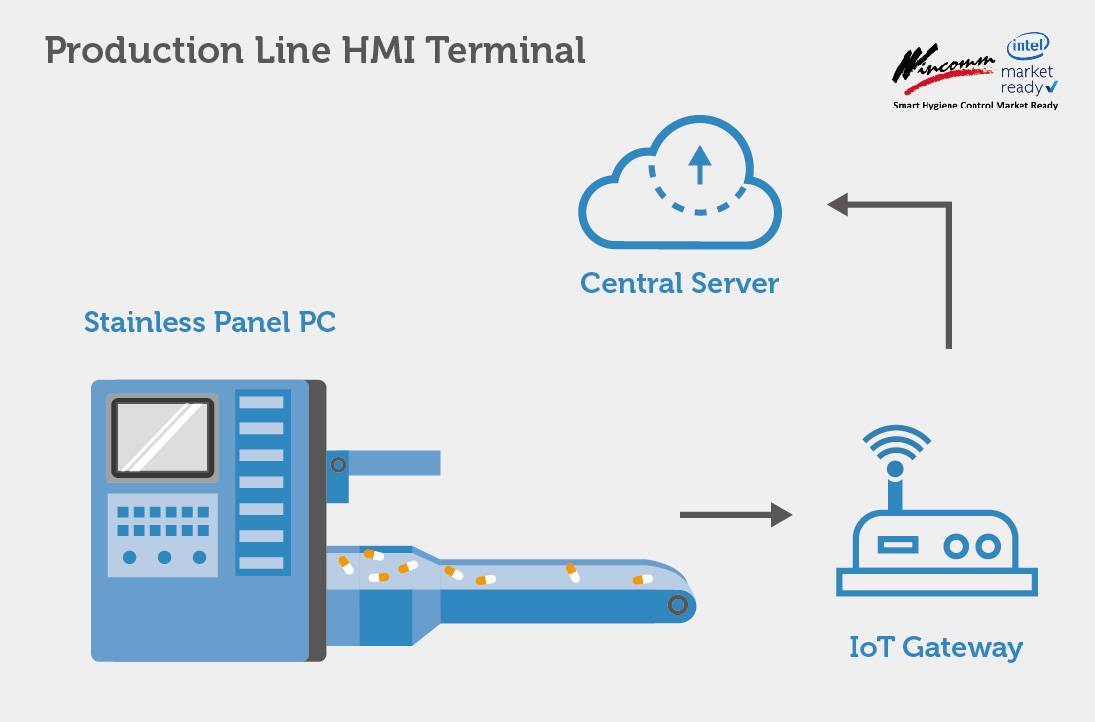

One part of the puzzle is to equip the food or pharmaceutical processing facility with the ability to provide smart hygiene control using special panel computers or box computers featuring high-power processors, six-sides IP69K protection applications.

- Monitor the environment to suit for pharmaceutical processing

The entire facility can also be equipped with a wide variety of microelectromechanical systems (MEMs) sensors so as to monitor things like temperature and humidity. Using this data coupled with their machine vision capabilities, the smart control systems can verify that consumables and pharmaceuticals are not left sitting in unsuitable environments for longer than recommended durations.

- Maintaining Clean and Sterile Environments

Multiple product recalls over the past few years—in conjunction with the current COVID-19 pandemic—have driven increasing awareness of the importance of hygiene in manufacturing and processing plants. As a result, there is now a requirement in pharmaceutical manufacturing and processing facilities for strict adherence to ingress protection (IP) against solids and liquids.

- Hygiene Control is Required the Standard – Waterproof & Dustproof

A rating of IP66 is fairly common and adequate for many pharmaceutical manufacturing and processing applications.

Wincomm Solutions

With Wincomm’s focus on designing strong rugged industrial computers, IP rated water and dust proofing has been a mainstay in our philosophy, which is exemplified through the technology needed for the IP69K Flat P-Cap Stainless Panel PC series. Designed as a machine controller or operator control PC for applications with high hygienic requirements such as the food and beverage or chemical processing industries, the IP69K WTP series is built to withstand extensive wash downs with corrosion resistance against cleaning agents, especially against close-range high-pressure, high temperature wash downs. Featuring at,

- Intel® Core™ or Celeron® Fanless Stainless Panel PC

- Panel Size Range from 10”, 15”, 19”, 22”, to 24”

- Multi-touch P-Cap or Single Touch Resistive Type

- IP66/69K Full Sealed with Anti-Corrosion Enclosure

- Special Inspection of 100% Waterproof Guarantee

- CE, FCC, VCCI Class B Certified to Secure Operator’s Health

- Screen Touch Lock Function for Easy Clean

- Robust Wireless Antenna

- Customization Service

For more product information, please visit the Wincomm website at https://www.wincommusa.com/

Related Products

|

|

|

|

| WTP-9G66-15 |

WTP-8D66-19 |

WTP-9E66-22W |

|

|

|

|