Revolutionizing Food Processing Operations with Advanced Freezer Control Panel

Project Background

The food processing industry is a critical component of the global supply chain, tasked with preserving the quality and safety of food from farm to table. Central to this mission is the effective management of freezing and cooling systems which play a pivotal role in extending the shelf life of perishable goods. However, the harsh conditions within these environments, coupled with the demanding hygiene standards, present significant challenges to the operational efficiency and reliability of conventional control systems.

Pain Points

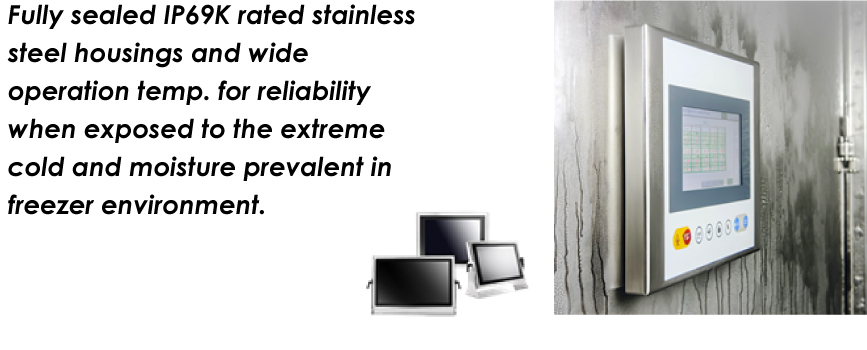

- Harsh Environmental Conditions: Traditional electronic control systems are prone to failure when exposed to the extreme cold and moisture prevalent in freezer environments, leading to downtime and potential compromise of food quality.

- Hygiene and Maintenance Challenges: The imperative to maintain stringent cleanliness standards necessitates regular washdowns, which can damage sensitive electronic components not designed to withstand direct exposure to water and cleaning agents.

- Operational Inefficiencies: A lack of real-time monitoring and control capabilities often leads to manual intervention, which is not only resource-intensive but also prone to human error, impacting the overall efficiency and productivity of the operation.

- Lack of Customization: Many food processing facilities operate with control systems that are not tailored to their specific needs, leading to inefficiencies and limitations in scalability and functionality.

Our Solutions

To address these challenges, Wincomm introduced the Wide Temperature Operation Waterproof Stainless Steel Panel PC, Full IP Wide Temp WTP series, a revolutionary solution designed specifically for freezer control panels in the food processing industry.

Durability in Extreme Conditions: Our Panel PCs are engineered to withstand the wide temperature ranges, from -20 to 60 degree c of food processing environments, from the deep cold of freezers to the variable temperatures of processing areas. The stainless steel casing provides an impermeable barrier against moisture and cold, ensuring uninterrupted operation.

.png)

Waterproofing for Enhanced Hygiene: Recognizing the importance of hygiene in the food industry, our Panel PCs are completely six sides waterproof and dustproof, up to IP69K, allowing for direct washdowns without the risk of damage. This feature ensures that the highest standards of cleanliness can be maintained without compromising the longevity or performance of the control systems.

Real-Time Control and Monitoring: Equipped with advanced sensors and automation capabilities, our Panel PCs offer real-time insights into critical parameters such as temperature and humidity. This level of control allows for immediate adjustments, optimizing conditions for food preservation and reducing the need for manual oversight. Moreover, it supported wireless solution with PCB type antenna and robust cover which makes it easy clean and no avoid damage with easy clean versus space saving benefits.

Customizable Solutions: Understanding that each food processing facility has unique requirements, our Panel PCs are highly customizable. Options include various screen sizes, processor capabilities, and input/output configurations, such as RFID / Barcode Reader and even USB type C, ensuring a perfect fit for every application and the flexibility to adapt to future needs.

Energy Efficiency: In line with our commitment to sustainability, these Panel PCs are designed for energy efficiency, reducing operational costs and contributing to a lower environmental footprint.

Conclusion

By addressing the specific pain points of the food processing industry with our tailored solutions, we are setting a new standard for operational excellence in freezer control. Our Wide Temperature Operation Waterproof Stainless Steel Panel PCs offer the durability, efficiency, and customization needed to meet the challenges of today and the opportunities of tomorrow.

If you have any product or customization requirements, please contact Wincomm sales (mail: sales_support@wincomm.com.tw). For more product information, please visit the Wincomm website at http://www.wincomm.com.tw/

Related Products

|

|

|

| Full IP Wide Temp WTP series |

Outdoor Rugged Solutions Product Series |

|

|

|