CNC Machine Control Solutions

CNC Machine Control Solutions

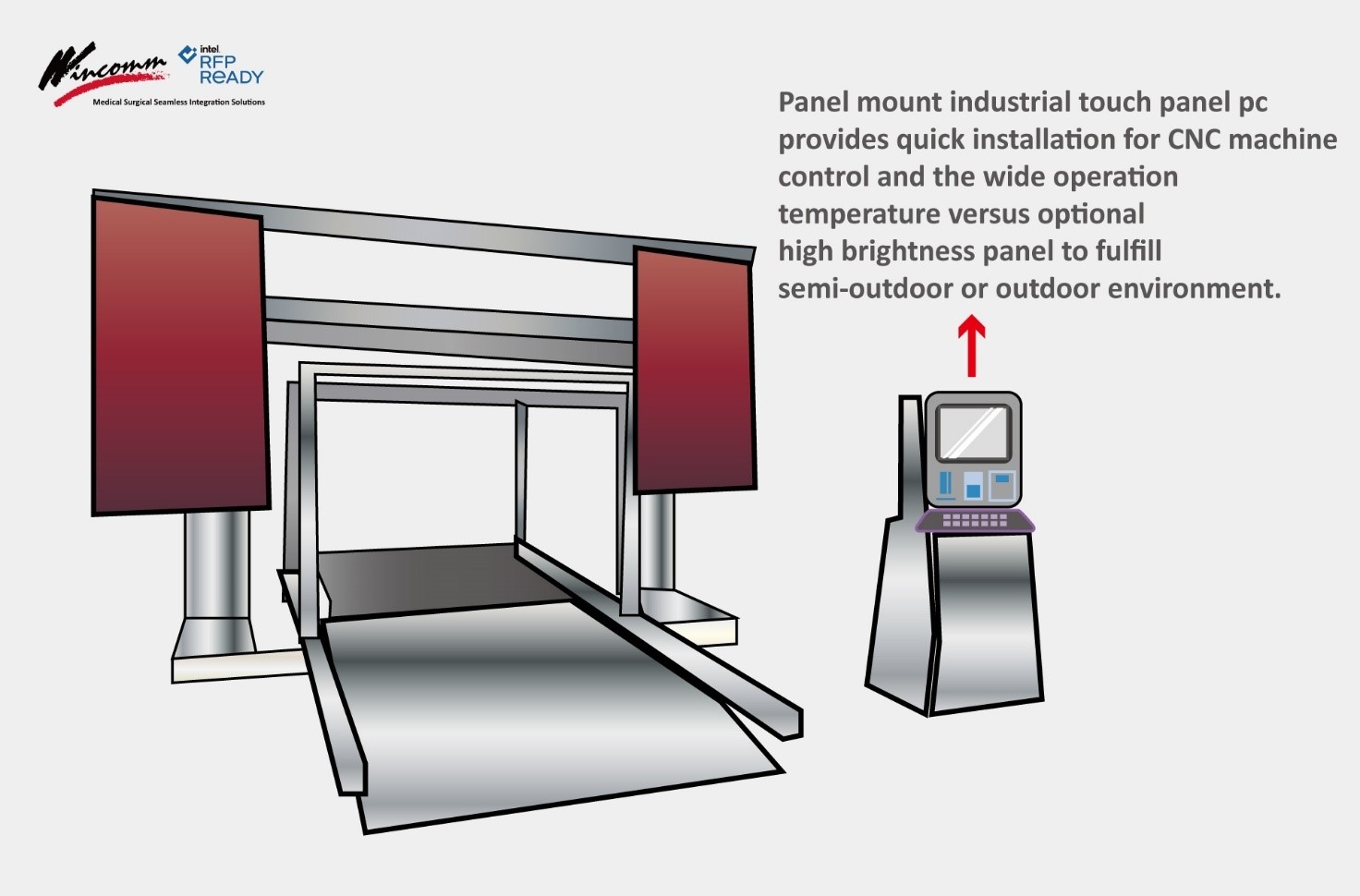

Background Computer Numerical Control (CNC) machines have redefined manufacturing, integrating precise computer control into machining processes. Operating in diverse environments, CNC machines automate milling, turning, and other processes, offering unmatched precision. From aerospace to electronics, their adaptability to various materials and environments enhances productivity, minimizes waste, and drives manufacturing innovation. This introduction explores the transformative impact of CNC machine control in wide operational environments, where precision and automation converge to shape the future of modern manufacturing. Computer Numerical Control (CNC) machine control alleviates the longstanding pain point of manual machining limitations in industrial environments. Traditional methods lacked precision, leading to errors, material wastage, and inefficient production. CNC machines revolutionize this by offering automated, highly accurate operations. They mitigate human errors, enhance repeatability, and navigate diverse materials with ease, ensuring consistent quality and minimizing waste. In the industrial landscape, CNC machine control resolves the challenges associated with manual processes, ushering in a new era of efficiency, reliability, and precision in manufacturing operation. To suit for wide temperature and sunlight readable requirement to fulfill bespoke CNC machine control under semi-outdoor to outdoor environment, the features must include.

Wincomm Solutions

|

|||||||

e-News Subscribe

e-News Subscribe